Robot Design

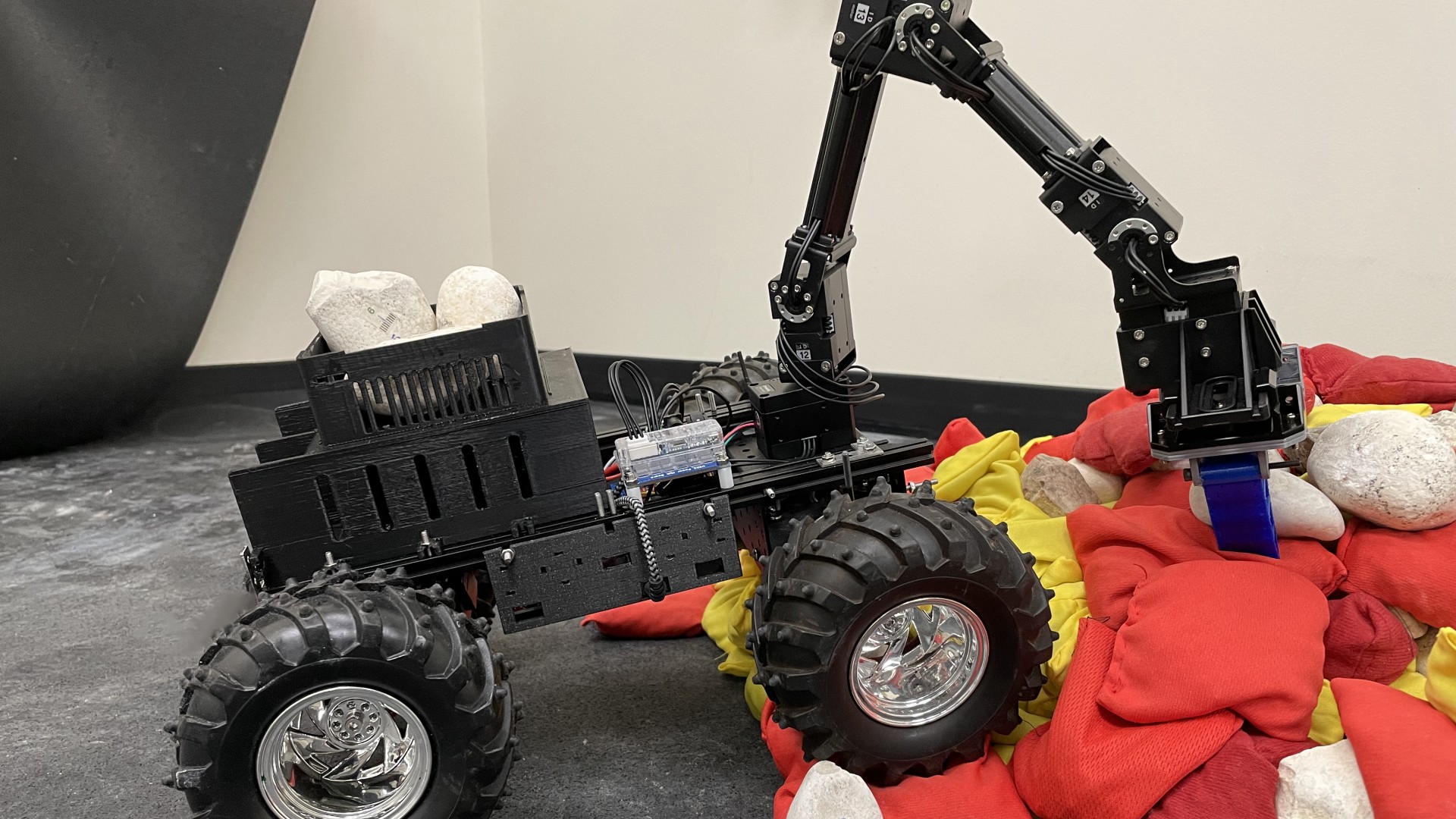

The robots are low-cost mobile manipulators made from off-the-shelf components, capable of maneuvering over irregular terrain.

[Scroll down for Version 4]

Version 1

RUFOUS

Version 2

CASTOR

Finalist | Best Systems Paper, RSS 2018

Version 3

PUFFER

Compute Module

Nvidia Tegra TK1

Quad-core 2.3GHz ARM Cortex-A15

Size: 127mm x 127mm x 25mm

DRAM: 2GB DDR3L 933MHz

Storage: 16GB fast eMMC

Power: 3 Watts

Intel Aero Board

Quad core 2.4 GHz Intel Atom x7-Z8700

Size: 88mm x 63mm x 20mm

DRAM: 2GB DDR3L 933MHz

Power: 2GB DDR3L 933MHz

Intel Up Board

Quad core 1.92 GHz Intel Atom x7-Z8350

Size: 85 mm × 56 mm x 20mm

DRAM: 4GB DDR3L 933Mhz

Storage: 32GB eMMC

Manipulator

uArm Metal

4 DOF / RC Servo Motors

Weight: 1.5 kg

Repeatability: 10mm

Max Lifting Weight : 500g

Work Range: 120 - 320 mm

uArm Swift Pro

4 DOF / Stepper Motors

Weight: 1.9 kg

Repeatability: 0.2mm

Max Lifting Weight : 500g

Work Range: 50mm - 320mm

uArm Swift Pro

4 DOF / Stepper Motors

Weight: 1.9 kg

Repeatability: 0.2mm

Max Lifting Weight : 500g

Work Range: 50mm - 320mm

Base Module

Wild Thumper 4WD Aluminium chassis

Spiked 120mm-diameter wheels

Individual Twist Suspensions

60mm Ground clearance

3D Printed Motor Housings v1

Brushed DC motor with Encoders × 4

Closed loop velocity control mode

Weight: ~ 2.8kg

Wild Thumper 4WD Aluminium chassis

Spiked 120mm-diameter wheels

Individual Twist Suspensions

50mm Ground clearance

3D Printed Motor Housings v1

Brushed DC motor with Encoders × 4

Closed loop velocity control mode

Weight: ~ 3.5kg

Customized Wild Thumper 4WD Aluminium chassis

Spiked 120mm-diameter wheels

Individual Twist Suspensions

60mm Ground clearance

3D Printed Motor Housings v2

Brushed DC motor with Encoders × 4

Closed loop velocity control mode

Weight: ~ 3.4kg

Power and Battery

7.4 DC LIPO Battery

DC-to-DC and Logic Level converters

Onboard Voltages: 5V/12V

Dual 7.4 DC LIPO Batteries

DC-to-DC and Logic Level converters

Onboard Voltages: 5V/12V

Power Monitoring Circuit

Automatic Shutdown and Restart between battery replacements

Dual 7.4 DC LIPO Batteries

DC-to-DC and Logic Level converters

Onboard Voltages: 5V/7V/12V

Power Monitoring Circuit

Sensors

Wheel Encoders 9600 counts/revolution

April Tag for Localization

Overhead Kinect v2 Camera

Wheel Encoders 9600 counts/revolution

April Tag for Localization

Power Monitoring Circuits

IMU

Realsense D415 Depth Camera

OpenMV Camera

Overhead Kinect v2 Camera

Wheel Encoders 9600 counts/revolution

April Tag for Localization

Power Monitoring Circuits

IMU

Realsense D415 Depth Camera

VGA Camera

Overhead Kinect v2 Camera

End Effectors

The robots are equipped with different end-effectors and camera modules based on their functionality. A gripper to handle compliant bags, a suction cup to handle foam blocks and a custom 1DOF gripper to handle previously unseen stones.

Bag Handler

The arm is modified to use a 1DOF generic gripper to pick up and deposit complaint bags. The overhead Kinect camera provides the location of the bags to the robot system. A pickup and deposit pose is calculated according to the robot design, environment and construction algorithm.

Detach Manuever

Castor detaches its arm's servo motors when the gripper is close to the bag allowing the open gripper to fall over. When the gripper is closed, the deactivated arm joints provide compliance for a better grip. The arm motors are then re-attached to lift the bag up.

Foam Handler

The arm is modified to use a 1DOF generic gripper to pick up and deposit complaint bags. The overhead Kinect camera provides the location and size of the foams to the robot system. A pickup and deposit pose is calculated according to the robot design, environment and construction algorithm.

Visual Servoing

Puffer uses a OpenMV M7 Camera, fixed on the end-effector of the arm, to align its suction cup to the AprilTag on a foam block. A contact switch on the end-effector assists the pickup planning. After pickup, the suction cup is rotated to align the block's minor axis with the robot axis.

Stone Handler

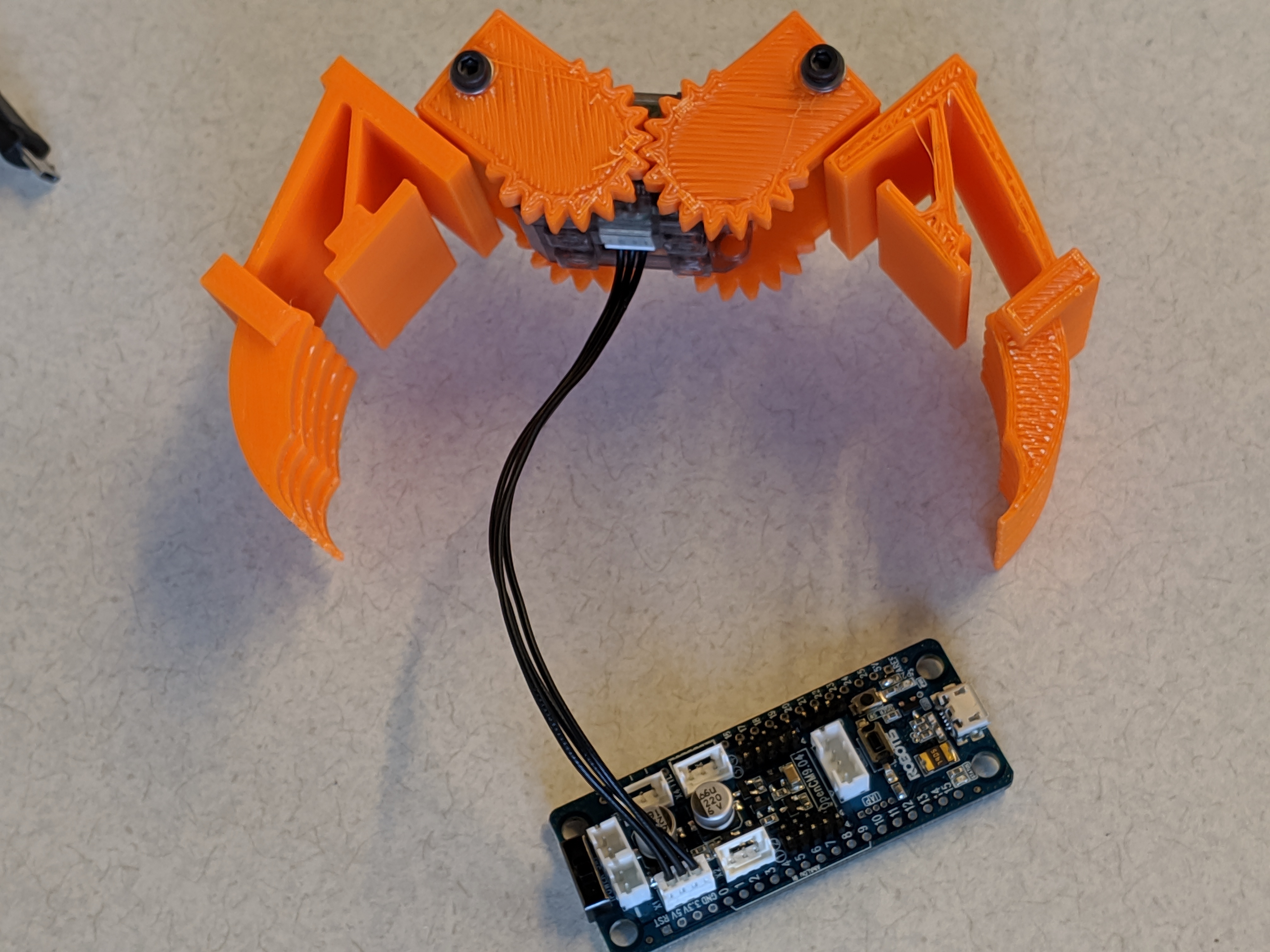

A 1DOF compliant gripper was designed to pickup previously unseen stones. The stones were chosen such that are within the payload requirements.

Design Limitations

The

Stone Crabber

is designed in accordance to the power, the arm's payload and the motor's thermal limitations. A XL320 Servo Motor with a torque of 0.39N-m weighs 16.7 g, the VGA camera module weighs at 25 g and the gripper weighs around 40g. The effective payload is now reduced to 210 g, but is large enough to pick up assorted small-to-medium sized river pebble rocks. The motor controller provides an approx. current-based torque feedback that allows for the gripper to effectively grip a stone without overheating during long run times.

Gripper Prototype

Using styrofoam on the gripper fingers increases friction and allows for a much better grip.

The fingers are

curved

while being

flat and thin

near the pick-up points to scoop the object.

Five parallel sub-fingers

are connected to the main rigid finger body through a flexure.

The

flexure joint

enhances compliance and increase friction after the initial grasping.

Stone Crabber

is a 1 DOF Pinch gripper designed to pick up stones.

A downward-facing VGA

gripper camera

is fixed on the end-effector of the arm.

The object pose with the

best "score"

is chosen as the deposition pose.

Version 4: Robot Design Concept

[Work in Progress]

A newer, modular and self contained robot system that can temporarily store stones for future construction tasks. The picture depicts a robot design concept.

A compliant gripper allows the robot to pick up previously unknown, found stones from a pile.

The compliant gripper fingers taper towards their tips to provide enough pinching force to also pickup small regolith bags. Picking up individual bags from a pile is an involved task. However, multiple bags picked up from a pile may be separated using environmental features. The video demonstrates this idea.

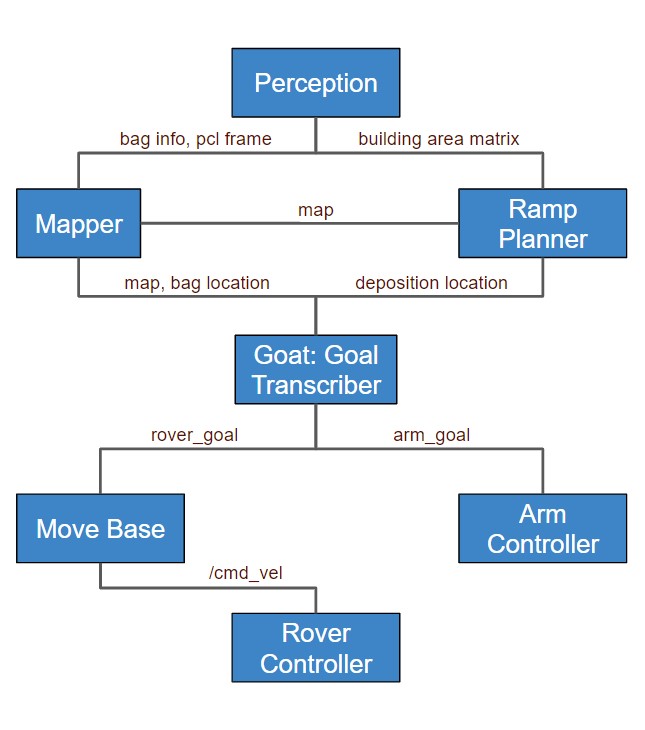

System Design

Node Architecture

The robot system is designed atop the ROS architecture. It allows us to use open source packages like the move_base navigation package and the AprilTag fiducial detection algorithm, while promoting modularity in our code base as well. The node architecture depicts the minimal set of nodes used in all the projects developed thus far.